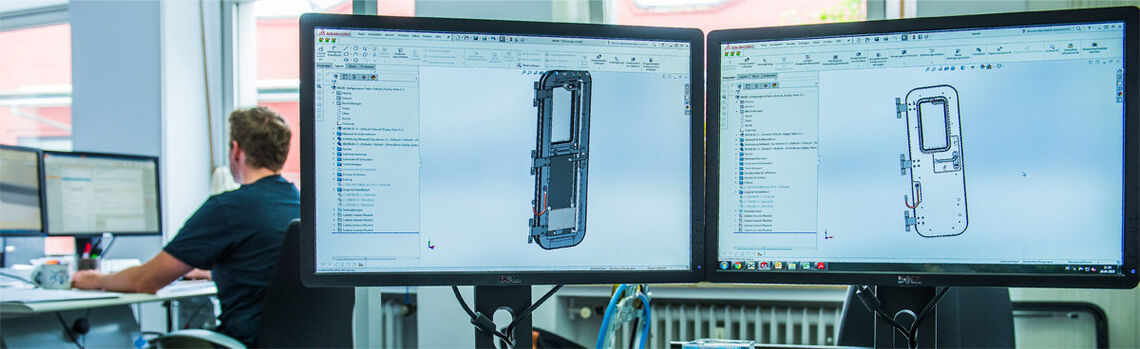

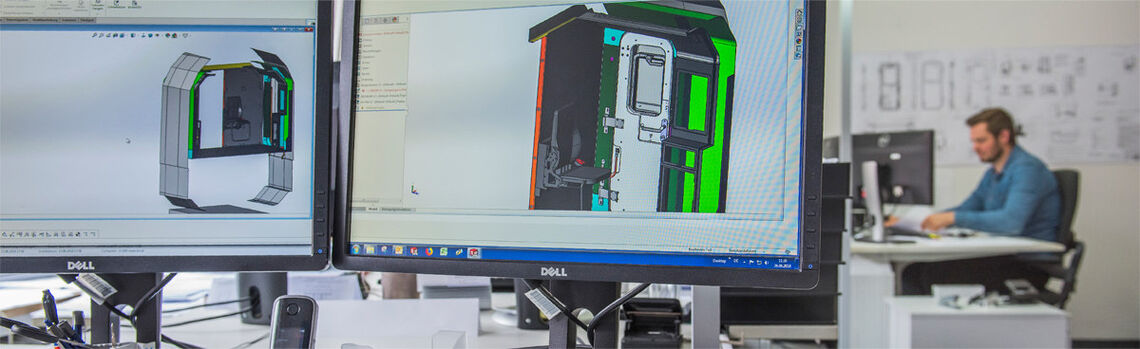

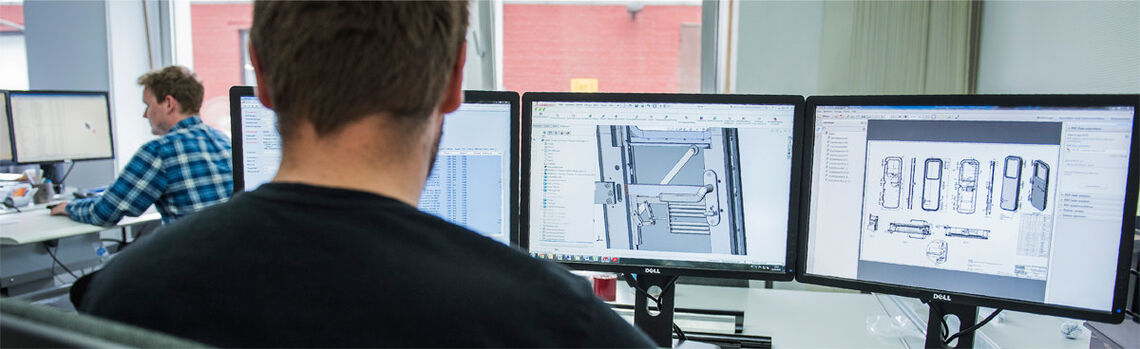

Development

We are looking back on a long tradition producing windows and doors wihtout losing the future out of sight. We ingest proactively the requirements for operating conditions that are frequently changing and we develop products that meet the expectations and wishes of our customers. Today, a product development with modern tools such as CAD/CAM

Construction

A „good“ construction is the key to success. Already in the tendering stage, we are setting much value on combining experience in production, quality management and product development in order to find the right solution and in order to continue during the phase of design. Because only the professionality and the cooperation of all involved domains makes a highly qualitative and final construct solution.

Innovation

We always make sure to achieve an added value for our customers by innovating our products. They should ensure the best possible usability during the entire life cycle but they also should avoid preventative and corrective measures of maintenance. Design and functionality have to build a unit in order to ensure the absolute acceptance of our products.

Test Centre

In our on-site Test Centre, diverse methods for tests of the specification requirements are available for our customers. Our test bench according to UIC actually is the basis of valid product tests. Furthermore, we have the possibility to do lifecycle tests in order to determine the permanent functionality and also potential indications of abrasion: These tests are some essential components to ensure the technical maturity of our products and innovations.